Is it time to invest in an automatic folding machine?

In 2014, over 141 billion letters were sent in the U.S. People may say that the use of mail is declining, but that's still a lot of mail.

Does your office or campaign have letter stuffing parties, taking away time from important business? An automatic folding machine would cut down the time needed and allow workers to focus on what matters most.

That can save your organization time and money.

Read on for how these devices work and advice to help you know what to look for when buying one.

Advantages of a Paper Folding Machine

A paper folding machine has many advantages.

Cost Savings

How much does an envelope stuffing party cost your organization? A folding machine can reduce the man-hours needed for massive mailings.

Faster Than a Person Folding Paper

How long does it take for one person to fold paper over an hour? They might get through 100 or so pieces.

An automatic folding machine such as a light-duty P6400 Martin Yale machine can fold 2,200 sheets per hour.

Reduce Human Errors

When people have been standing around folding paper and stuffing envelopes for hours, they get tired. Their minds wander, and they get distracted. That raises the possibility of letters getting stuffed in the wrong envelope or mixed up.

It's very difficult for a person to fold paper the exact same way every single time. That can lead to addresses not appearing in the envelope window, or missing pages.

A folding machine will also ensure consistent folds every time.

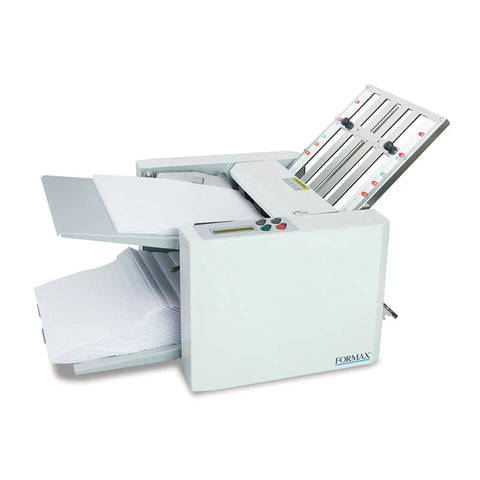

The Major Parts of a Folding Machine

In order to understand how a paper folding machine works, it helps to go over the different components of the machine. You may be surprised to know that there are only five key parts of a folding machine.

Input Tray: This is simply where you feed the paper into the machine. Just like most printers, you can adjust the input tray according to paper size.

Pickup Roller: This is also called a friction feed roller. It's usually made of rubber and is a larger roller that feeds the paper into the folding machine and brings it to the first plate.

Fold Plates: Machines usually have two or more fold plates, depending on the capacity of the machine. A fold plate is where the paper is fed and folds are created.

Fold Rollers: These are smaller rollers that keep the paper moving along a straight line, which creates a clean, consistent fold.

Fold rollers to a lot of work, so it's important to maintain them to keep your automatic folding machine running smoothly. Dust can build up on the rollers and they can wear down over extended use. It's a good idea to clean them often with a preventative maintenance kit.

Exit Tray: This is where the paper goes once folding has been completed.

The durability of the parts will depend on the manufacturer. You can get something more durable than a Lego automatic folding machine.

That's why it's important to consult with experts before you buy.

How Does an Automatic Folding Machine Work?

A paper folding machine is a great piece of machinery. It's simple, and incredibly functional at the same time. Here's how it works once you place the paper in the tray:

The machine will bring in the paper using its wheels, which are typically made of rubber.

The first plate pushes and pulls the paper back and forth, then it will get to the second plate.

As the paper goes between the two plates, a rubber roller will fold the paper.

The paper will leave the machine and land on a tray, or bin. That would depend on your machine's configuration.

Types of Folding Machines

There are three types of paper folding machines. Each one has its own sets of features and benefits.

Manual Fold Adjustment

A manual fold adjustment machine means that you need to change the fold plate settings by hand. That means that the quality of the fold depends on you setting the fold plates exactly right. You have to make sure that the plates are square. Otherwise, you'll get paper with crooked folds.

On the plus side, these can be adjusted to create customized folds. These are also fine if you don't need many built-in folds.

There's a wide range of manual fold adjustment machines. They can be a great fit for heavy duty use or can be an economical solution depending on your needs.

Automatic Fold Adjustment

You can probably guess that an automatic fold adjustment means that you don't have to adjust the fold plates yourself.

You should consider an automatic fold adjustment machine if your jobs require multiple types of folds. This way, you're not spending time resetting fold plates for every fold. The time spent on that would defeat the purpose of having an automatic folding machine to begin with.

Air Fed Machines

Earlier, we discussed how a paper folding machine works and how friction rollers are used to feed the machine.

With an air fed machine, a vacuum is used to feed the machine instead of rollers.

Which type of machine is right or your organization? It depends.

What type of paper will you use? Thicker or digital paper might stick together. In that case, an air fed machine would be better.

What type of volume are you planning to do? Air fed machines are built for high-volume work and are appropriate for print shops and any other heavy-duty environment.

Questions Before You Buy an Automatic Folding Machine

There's a lot to know and understand about paper folding machines. It's a big investment that can have huge dividends, as long as you buy the one that fits your needs.

Our team of paper folding machine experts is here to help you determine the best product for your organization.

Get all of your questions answered by contacting the Paper Folding Pros today.